Repmold refers to a molding technique based on replication. The word itself comes from “replicate” and “mold.” Instead of making one mold and discarding patterns, it lets you produce reusable molds that create exact copies. The process emphasizes accuracy, repeatability, and flexibility, so you can prototype or produce parts with minimal waste. In simple terms, with this technology, you first design a master pattern (using CAD, 3D printing, or CNC), then you form a mold around that pattern using durable materials. That mold can be reused many times. The result is a series of parts that match the original master closely.

How Repmold Works

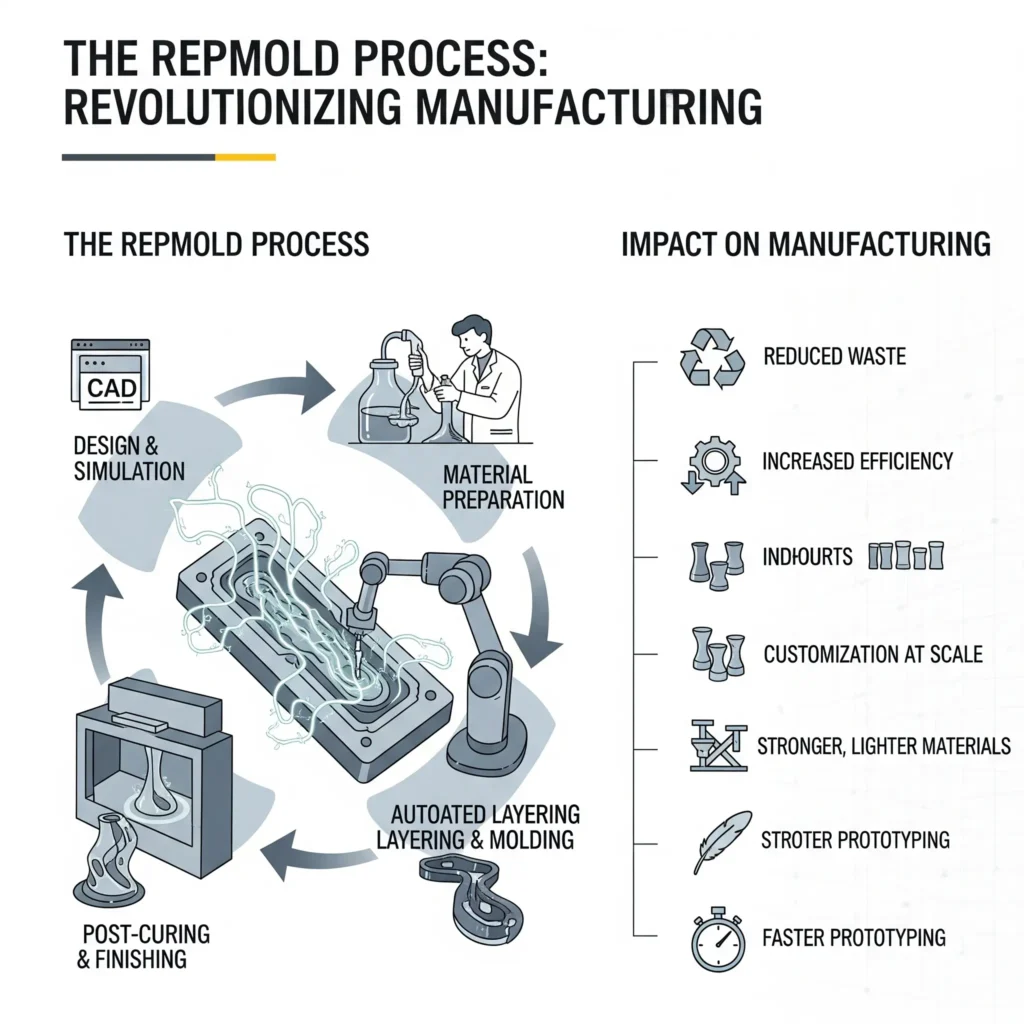

Step-by-Step Process of Replication Molding

- Design & Master Pattern Creation

Engineers or designers make a master model using CAD tools. This model is then fabricated, typically via 3D printing or CNC, to match exact specifications. - Mold Formation

The master pattern is used to form a mold. Mold materials like silicone, epoxy, or composites are chosen based on the application. - Curing or Hardening

The mold material is allowed to cure or harden fully to ensure it holds shape and detail over multiple uses. - Replication of Parts

Once the mold is ready, it’s filled with the final production material (resin, plastic, etc.) to replicate the part. - Post‑Processing & Quality Control

After de-molding, parts may need trimming or finishing. Inspection ensures consistent quality across batches.

Key Benefits of Repmold

Speed and Fast Turnaround

It shortens the timeline from design to finished product. It’s ideal for prototyping and rapid development.

Cost Savings

Reusable molds reduce the need for costly tooling. Less waste and quicker iterations further reduce costs.

High Precision & Consistency

Parts made using it are nearly identical, which is crucial in industries where tolerances matter.

Flexibility and Adaptability

Designs can be changed quickly by modifying the master pattern and creating a new mold.

Sustainability and Waste Reduction

Fewer tools and lower material waste make it more environmentally friendly.

Applications of Repmold in Various Industries

| Industry | Use Cases | Benefits |

|---|

| Automotive | Trim panels, dashboard parts, small components | Quick testing, cost savings |

| Medical Devices | Prosthetics, tool casings, surgical accessories | High accuracy, hygiene compliance |

| Consumer Electronics | Custom shells, internal components | Quick turnaround, lower volume flexibility |

| Consumer Goods | Kitchen tools, toys, decorative items | Easy customization, low cost |

| Education & R&D | Prototyping, student projects | Hands-on learning, rapid iteration |

It bridges the gap between handcrafted production and industrial-scale manufacturing.

Repmold vs Traditional Mold Making

Comparison Table:

| Feature | Traditional Mold Making | Repmold |

|---|---|---|

| Tooling Cost | High (steel molds) | Low (reusable materials) |

| Lead Time | Weeks to months | Days to weeks |

| Design Changes | Difficult and expensive | Fast and affordable |

| Durability | Extremely long-lasting | Moderate, depends on material |

| Volume Suitability | Ideal for mass production | Best for low to medium volumes |

Challenges and Limitations

Durability of Molds

It molds may not survive extreme pressure or extended runs like hardened steel molds do.

Material Compatibility

Some materials may degrade or damage softer molds, especially under high heat or friction.

Limited Volume Production

For millions of parts, traditional molds are more cost-effective over time.

Precision Cost Trade-offs

Highly polished surfaces or complex parts may require more advanced—and expensive—mold materials.

Strict Quality Control

Small errors in the master pattern will repeat. This requires robust QA throughout the process.

Key Considerations: What You Need to Plan For

- Choose the Right Mold Material: Based on part volume, complexity, and durability.

- Master Pattern Tools: CAD, CNC, or 3D printers are essential.

- Inspection & QA Setup: Ensure tolerances are monitored and deviations corrected early.

- Estimate Run Volume: It works best for small to medium batches.

- Sustainability Goals: Select eco-friendly resins and limit disposable waste.

Future Trends, where the technology is heading

Advanced Mold Materials

New composites will make it molds last longer and work with tougher resins.

3D Printing + Repmold

3D-printed patterns and inserts will reduce lead times even further.

Simulation and AI Feedback

Mold behavior can be simulated to avoid failure points, and sensors can provide real-time data.

Automation & Smart Molds

IoT sensors will enable predictive maintenance and smarter production.

Sustainability Integration

Eco-friendly molds and greener workflows will make it a key player in green manufacturing.

More SME Adoption

As costs drop, small and medium-sized businesses will embrace it for customized production.

Case Studies: Practical Examples

Consumer Startup

A kitchenware startup created molds via it for product testing and early sales—cutting costs by 60%.

University Lab

Engineering students use it in labs to replicate functional prototypes for competitions and patents.

Medical Device Firm

A company developed surgical housing components using it, which helped them meet testing deadlines faster.

Electronics Brand

A company testing 4 different product casings used it to produce batches of 200 units each—avoiding high steel mold costs.

FAQs

Q1: What exactly does repmold mean?

A: It stands for replication molding—a method of using a reusable mold to replicate exact copies of a master part.

Q2: Is repmold the same as 3D printing?

A: No. 3D printing creates objects layer by layer. It uses a master model to form a mold and cast multiple copies.

Q3: What materials are used in repmold molds?

A: Common materials include silicone, epoxy, polyurethane, or composites, depending on part design and requirements.

Q4: How many parts can a repmold mold produce?

A: Typically hundreds to a few thousand. Durability depends on the mold material and the working environment.

Q5: When should I use repmold instead of traditional mold making?

A: Use it when speed, flexibility, and cost-saving matter more than ultra-high volume or extreme durability.

Conclusion

Repmold is transforming modern manufacturing. It provides a fast, cost-effective, and sustainable alternative to traditional molding for prototyping and small-batch production. While it’s not a perfect solution for high-volume industrial manufacturing, its adaptability, speed, and affordability make it a powerful tool for designers, startups, and innovators. As industries push toward greener and more agile methods, it stands out as a practical, forward-looking solution that merges technology, creativity, and efficiency in the manufacturing process. For more informative content and real reviews, visit this website.